Celiber Production

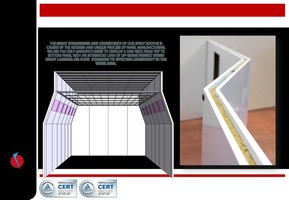

Celiber have a spraybooth to suit you, bringing your repair center into the modern era.

Celibers manufacturing facilities

- Spraybooths

- Small car size to double commercial

- Door entry height to suit you (3m standard)

- Various fuel combinations

- Daylight flourecent tubes

- Any floor ectraction type (inc int ramp option)

- Modern cosmetic finish for todays repair center

- Energy efficient Variable Speed Drives

- Preperation Bays

- Cost effective double bays

- Single plant operation for double bay area

- Raised or flat bases

- Low maintenance for long life durability

- Modern cosmetic finish for todays repair center

- Paint Mix Rooms

- Mix room intergrated to blend in with your complex

- Any size to suit

Questions about our product? Please contact us.

Celiber Spraybooth Range

| Spray Booth CLASSIC | |

|

Five different types of basement from civil work to metallic to choose, with grating and paint stop filters Front with three or four leaf doors with windows, center door has antipanic security lock. Rigid panels manufactured in one piece filled with high density rock wool isolation. Lighting assured: 1200 LUX. Impulsion extraction motor groups with reaction direct transmission turbines. Pressure controlled manually. Analog control panel. Standard diesel, gas or gas with direct combustion burners available in different power versions. European normative complied UNE-EN 13355. Dimensions and features adapted personally for every project |

|

|

|

|

|

|

|

| Five different types of basement from civil work to metallic tochoose, with grating and paint stop filters Front with three or four leaf doors with windows, center door has antipanic security lock. Rigid Panels manufactured in one piece filled with high density rock wool isolation. Lighting assured: 1200 LUX. Impulsion extraction motor groups with reaction direct transmission turbines. Pressure controlled automatically regulated by frequency variator INVERTER in extraction motor. Automatic control panel with touch screen. Standard and direct combustion burners available in different power versions. European normative complied UNE-EN 13355. Dimensions and features addapted personally for every project. |

|

| Preparation Area GRAND AVANTGARDE | |

|

Civil work or metallic box basement, with grating over Paint-Stop filters. |

|